We also provide both a competitive injection mould making and injection moulding facility, offering speed and flexibility in producing small precision plastic mouldings, in quantities to meet the customer’s requirement.

We welcome the opportunity to discuss complete projects from an early stage, and have the facilities to produce the type of mould tool that best suits your requirements, be it for prototypes, low or high volume production quantities. The tools are then transferred to our modern moulding facility for samples, and subsequently, production.

We produce quality component parts for the Telecommunication, Medical, Electronic and Automotive industries.

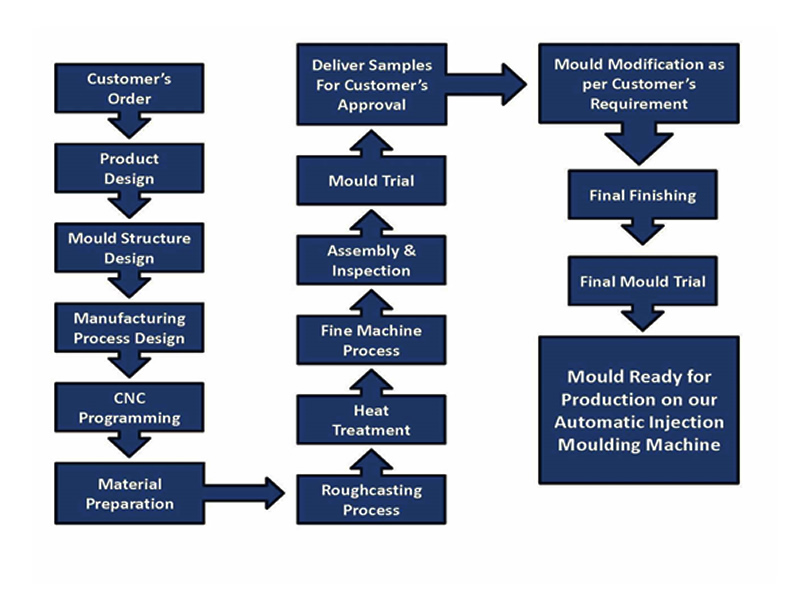

We have always been determined to serve the Plastics Industry with Precision Design and Mould Manufacture. Careful engineering and planning are crucial to producing a quality mould. The utmost attention is given to material properties and characteristics to determine optimal production efficiency. Our experience in mould design and development allows us to take your tooling requirement, from the initial concept stages through to final mould manufacture with professional expertise, care and diligence.

We aim to provide a competitive on time service for:

- New products

- Inhouse Tooling and moulding configurations

- Existing moulding projects

- One off tools

- Timely Delivery of finished components

- Flexibility to cope with our customer’s exact requirements

- Wide Knowledge & skill in Plastics

- Expert Advice

- Fast reliable service

- Very competent rates

Our reputation is based not only on the quality of our moulds but also our fast, efficient and friendly service, technical knowledge and after sales care. We have developed as a company to offer a complete package, which covers all aspects of mould technology, form initial design, prototype tools through to full production moulds.

Moulding

We have moulding machines, ranging from 25t to 130t lock, are used offering a fast and reliable production method ensuring that consistently good quality mouldings are produced 24 hours a day.

Insert moulding using brass, steel or plastic inserts is carried out on automatic machines.

Engineering materials including Nylon, Polycarbonate, HIPS, ABS, GPPS & SAN are processed, as well as commodity materials such as Polypropylene, LDPE and HDPE.

A range of post moulding operations can be carried out, such as the installation of threaded inserts, printing and specific packing requirements.

We have been located in Bhiwadi Industrial Area Near New Delhi, India since 1987, and now occupy a total of 1500 square metres. We have been ISO 9001:2015 certified by TUV –NORD.

We deliberately remain a company that is small enough to care, ensuring that the customer receives the best possible service.